Mechanical Design

How the robot was designed to house its components while maintaining structural integrity.

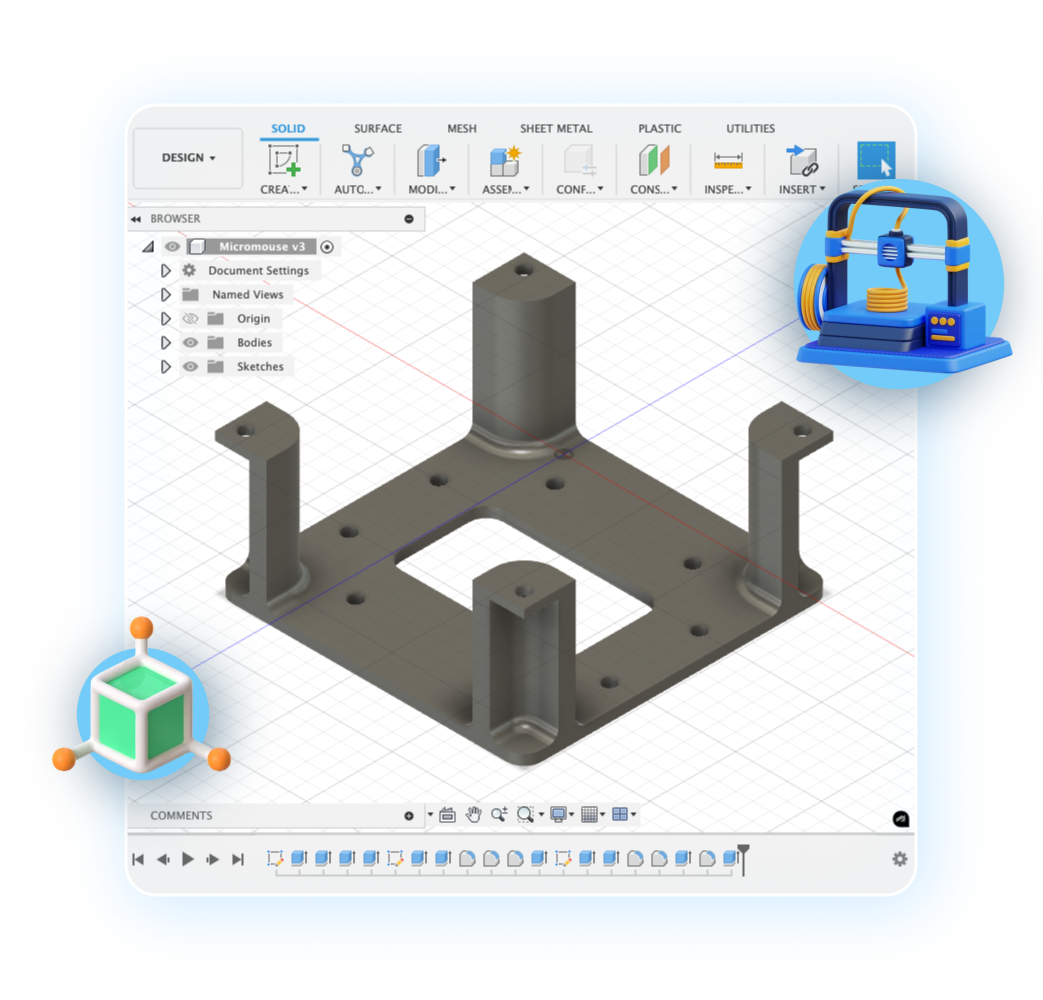

3D CAD: Several prototypes were carefully sketched and reiterated thanks to history tracking in software like Fusion 360.

3D Slicing: Infill percentage and support type were thoughtfully chosen, considering the structural loads on the chassis and multiple cavities.

3D Printing: PETG polyester material was prioritised due to its durability and good layer adhesion compared to other materials like ABS & PLA.

Bilal

Bilal